Printing one color at a time.

We’re the print house that sees screen printing for what it is—an art form.

-

High Quality

-

Quick Turn Around

-

Affordable Pricing

-

Decades of Experience

High Quality

Quick Turn Around

Affordable Pricing

Decades of Experience

High Quality Quick Turn Around Affordable Pricing Decades of Experience

We are definitely not your standard office printer.

Screen printing is a process with centuries of history and development. Its versatility and experimental nature is why it remains a trusted technique among artists and designers.

Got a project in mind?

The Art of Process

There is no magic “Print” button for screen printing. We don’t mind the steps, it’s part of the artistry and craft. Each step is another opportunity, and seeing it all come together is the reward.

-

This is where it all starts. Once we receive artwork, files must be separated for the silkscreen process. Because only one color gets printed at a time during silkscreening, artwork must be separated by color and arranged lightest to darkest, although some exceptions may apply. Once colors are separated and arranged, they must be trapped under each other to ensure all colors are flush.

-

Once artwork is prepared, it is laid out for outputting film. Each color gets its own film including bases, UV clears, and matte finishes. All films must be checked for correct alignment of each color. Outputted films then get burned to a screen which is then used in the printing process.

-

Printing begins with the first and lightest color being printed on all sheets and checking for no loss in detail and no color difference from the original artwork. When all sheets have received the first color, the printers can move onto the next color in line. This process is repeated until the last color, clear coat, or matte finish has been applied.

-

Once all sheets have come off the press and been approved, their borders and bleeds are trimmed off or die-cut to the artists’ requested shape and size. All cut posters and stickers are then packaged for delivery and shipped. Screens are then washed and reused for future jobs.

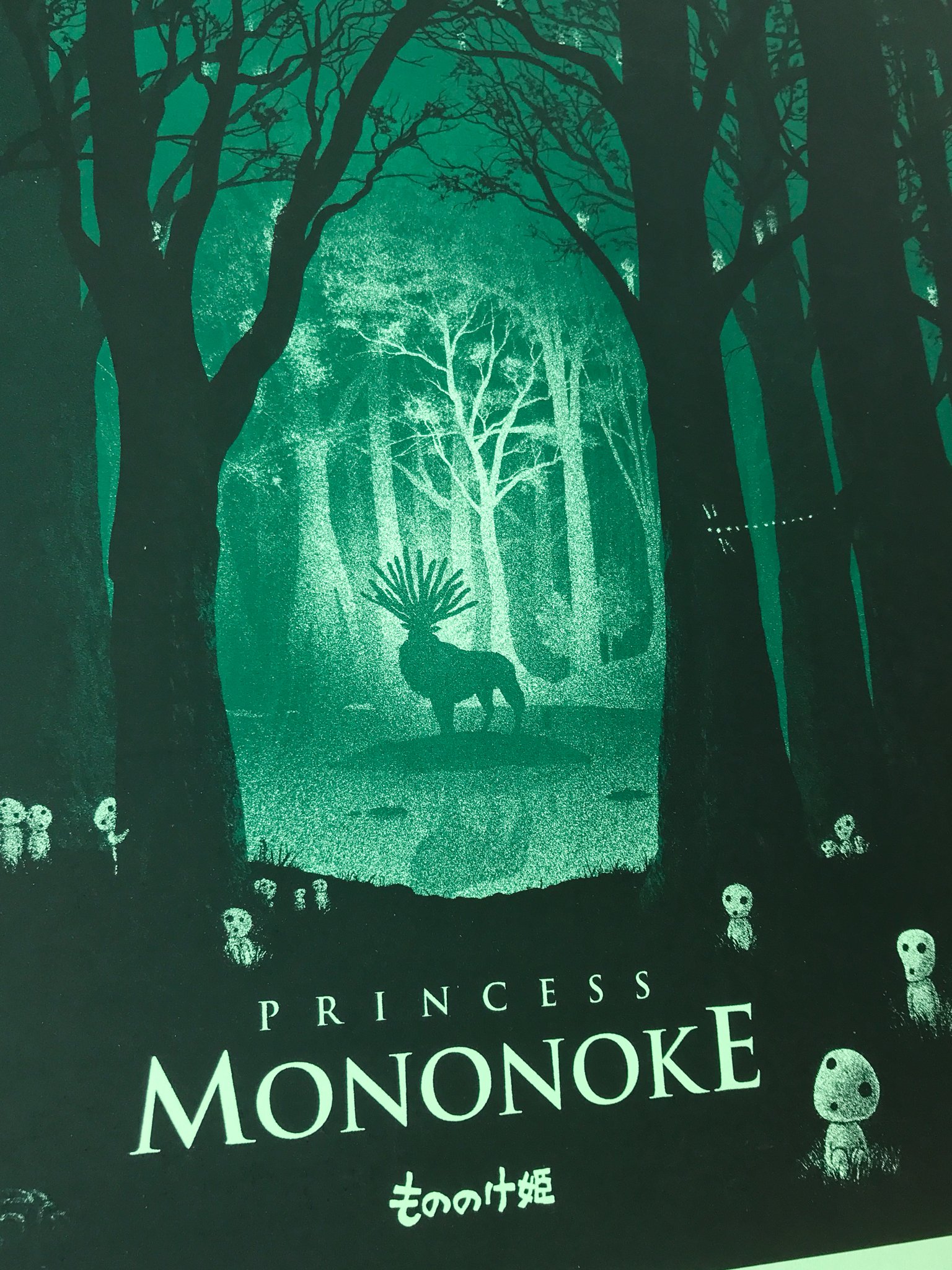

We like to let the print speak for itself.

Every project that passes through our presses is unique. It’s not easy choosing favorites, but there are a few memorable jobs we can’t help but talk about.